What is the strength of steel channels?

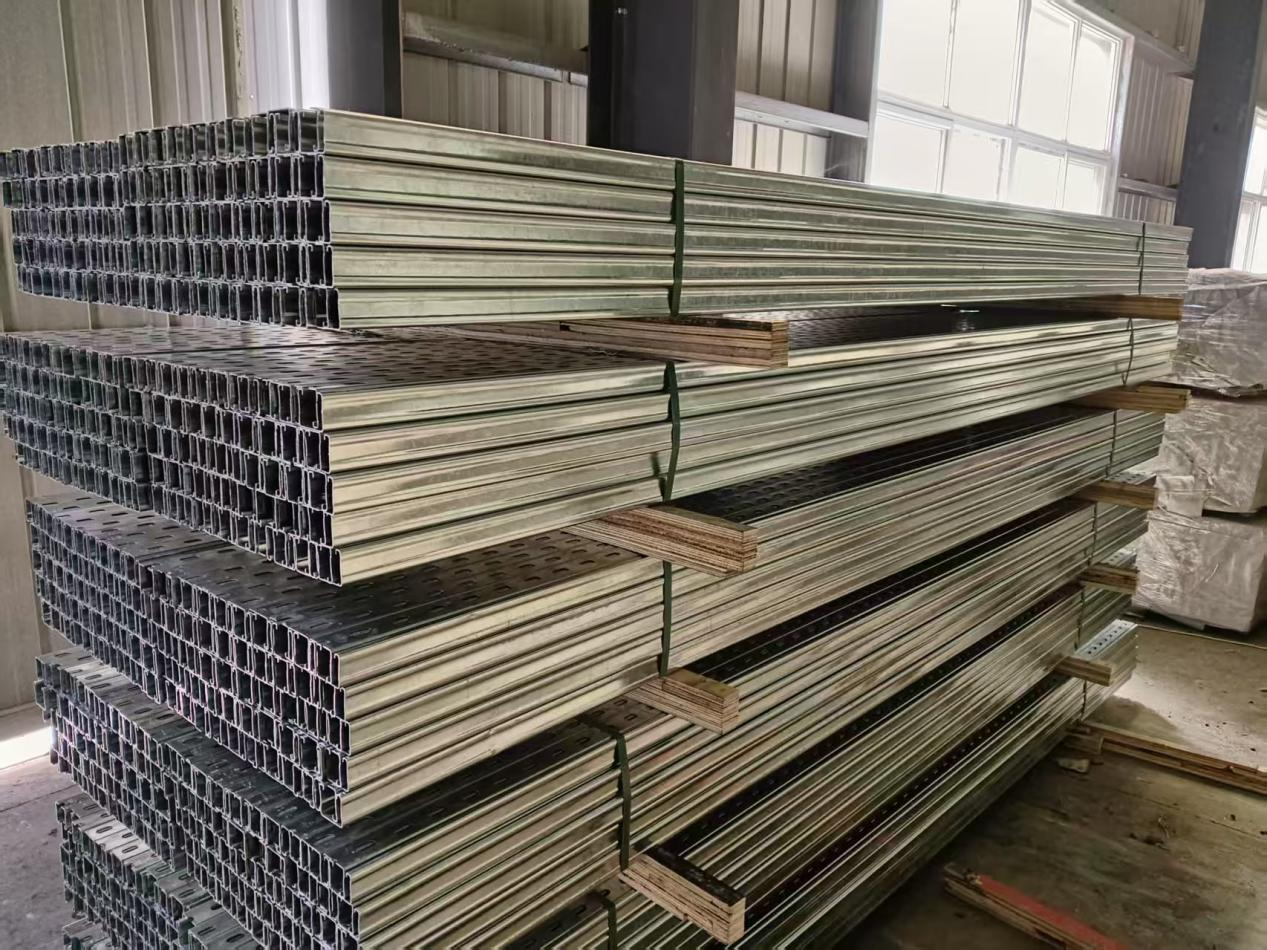

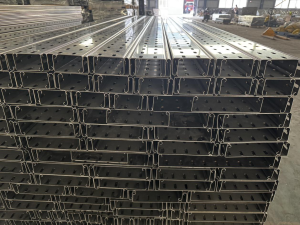

Steel channels are an essential part of the construction and manufacturing industries and are known for their versatility and strength. Shaped like a “C” or “U”, these structural elements are commonly known as unistrut channel, strut channel, c channel and u channel. They are commonly used in a variety of applications from building frames to support beams. Understanding the strength of steel channels is essential for engineers, architects and builders when designing structures that require durability and stability.

The strength of steel channels is determined by many factors, including its material properties, size and cross-sectional shape, and processing. Steel, as a material, is known for its high tensile strength, which allows it to withstand large forces without deforming. The yield strength of structural steel is usually between 250 MPa and 350 MPa, depending on the grade of steel used. This means that steel channels can withstand heavy loads while maintaining their structural integrity.

The size of a steel channel plays a vital role in its strength. Channels come in a variety of sizes with different flange widths, heights, and thicknesses. The moment of inertia is a measure of an object’s resistance to bending and is a key factor in determining how much load a channel can withstand. The greater the moment of inertia, the stronger the channel and the greater its ability to resist bending under load. Engineers often refer to standardized tables that provide the properties of different steel channel sizes, allowing them to select the right channel for a specific application.

The load-carrying capacity of a steel channel is affected by its orientation and the type of load it is subjected to. When the channel is oriented vertically, it can effectively support axial loads, while a horizontal orientation is better suited to resisting bending moments. In addition, the type of load, whether static (constant) or dynamic (changing), will also affect the performance of the channel. For example, steel channels used in bridges must be designed to withstand dynamic loads from vehicles, while channels used in building frames may primarily support static loads.

Steel channels are used in a variety of applications due to their strength and versatility. In construction, they are used as beams, columns, and brackets to provide necessary support to structures. In manufacturing, they are often used to manufacture machinery and equipment. They are easily welded, bolted, or riveted, making them a top choice for many projects.

While steel channels are strong, they are also susceptible to corrosion, which can weaken their structural integrity over time. To combat this, many steel channels are treated with a protective coating or are made from galvanized steel, which increases their resistance to rust and extends their lifespan. Regular maintenance and inspections are essential to ensure that steel channels remain strong and functional throughout their service life.

In summary, steel channels are an extremely strong structural element that play a vital role in a variety of industries. Their strength is affected by material properties, dimensions, and processing. By understanding these factors, engineers and builders can effectively utilize steel channels to build safe and durable structures. Whether in construction, manufacturing, or other applications, the strength of steel channels makes them an integral component of modern engineering.